Ro 4216 Niobium Alloy High Purity 99.95% Niobium Machining Spare Parts

Product Details:

| Place of Origin: | CHN |

| Brand Name: | HMD |

| Certification: | SGS, BV, TUV, LR |

| Model Number: | HMD-Nb |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Piece |

|---|---|

| Price: | USD 50-100 per KG |

| Packaging Details: | Export standard package with polywood case or ISPM 15 stamped wooden case |

| Delivery Time: | 25 Days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 Tons Per Year |

|

Detail Information |

|||

| Material: | Niobium | Density: | 8.57 (g Cm−3) |

|---|---|---|---|

| Melting Point: | 2410 °C | Boiling Point: | 5100 °C |

| Status: | Anneal | Surface: | Bright |

| Highlight: | Ro 4216 Niobium Alloy,Ro 4216 Niobium Machining Spare Parts,99.95% Niobium Machining Spare Parts |

||

Product Description

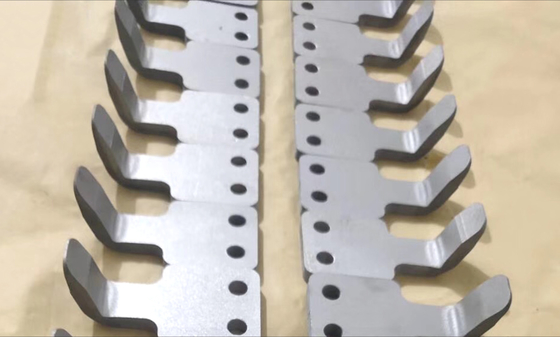

High Purity 99.95% Ro 4210/4216 and the Alloys Machining Spare Parts

Description

Niobium is a shiny, white, soft, and ductile metal, and takes on a bluish cast when exposed to air at room temperatures for a long time. The metal starts to oxidize in air at 200°C, and when processed at even moderate temperatures must be placed in a protective atmosphere.

Uses of Niobium

- It is used in stainless steel alloys for cutting tools, nuclear reactors, jets, missiles, and welding rods.

- It is used in the manufacturing of MRI scanners and NMR equipment.

- Its alloys are used in making surgical implants.

- It is used for the production of stainless steel and high-temperature resistant alloys.

TABLE 1. Chemical Requirements:

| Content, Max, Weight % | ||||

| Element | Grand: R04200 | Grand:R04210 | Grand:R04251 | Grand:R04261 |

| Unalloyed Niobium | Unalloyed Niobium | (Reactor grade niobium-1% Zirconium) | (Commercial grade niobium-1% Zirconium) | |

| C | 0.01 | 0.01 | 0.01 | 0.01 |

| O | 0.015 | 0.025 | 0.015 | 0.025 |

| N | 0.01 | 0.01 | 0.01 | 0.01 |

| H | 0.0015 | 0.0015 | 0.0015 | 0.0015 |

| Fe | 0.005 | 0.01 | 0.005 | 0.01 |

| Mo | 0.01 | 0.02 | 0.01 | 0.05 |

| Ta | 0.1 | 0.3 | 0.1 | 0.5 |

| Ni | 0.005 | 0.005 | 0.005 | 0.005 |

| Si | 0.005 | 0.005 | 0.005 | 0.005 |

| Ti | 0.02 | 0.03 | 0.02 | 0.03 |

| W | 0.03 | 0.05 | 0.03 | 0.05 |

| Zr | 0.02 | 0.02 | 0.8~1.2 | 0.8~1.2 |

| Nb | Remainder | Remainder | Remainder | Remainder |

TABLE 2.Mechanical Requirements:

| Grade(UNS) | Annealed | ||

| Tensile strength min, psi (MPa) | Yield strength min,psi (MPa)(2%) | Elongation min, % (1 inch gage length) | |

| R04200, R04210 | 18000 (125) | 10500 (73) | 15~20 |

| R04251, R04261 | 28000 (195) | 18000 (125) | 15~20 |

| R04220(RRR grade) | 14000 (95) | 7200 (50) | 30 |

![]()

![]()

Want to Know more details about this product